RAS machines for: Metal ceilings

Manual loading/unloading of ceiling panels

Manual loading and unloading of the RAS Multibend-Center panel bender can also achieve very short cycle times. The video shows manual blank loading and unloading of ready-to-use ceiling cassettes. Blank measuring (squaring) takes place parallel to the bending time. This reduces the time from part-to-part to 4 seconds.

www.hunterdouglasgroup.com

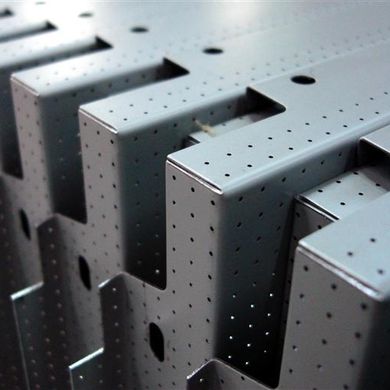

Bending of ceiling panels

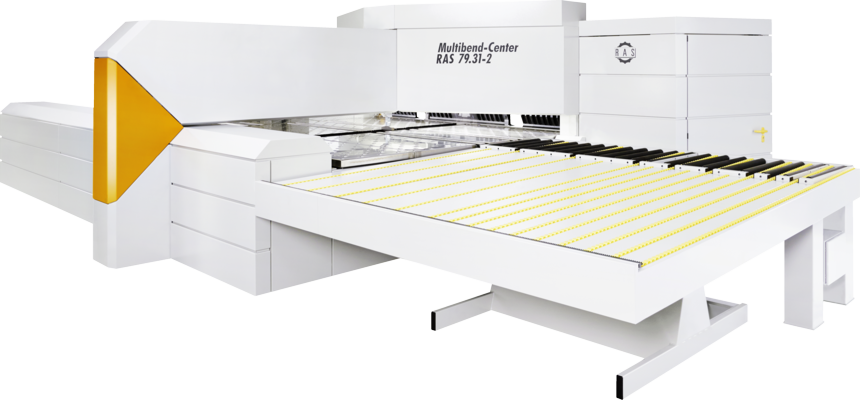

The company Schmid GmbH bends ceiling panels in rectangular and special shape on the RAS 79.31-2 Multibend Center. On many parts the process starts with a STEP file. After having imported the 3D data into BendexOffice the software creates the program with a single mouseclick.

www.schmidgmbh.de

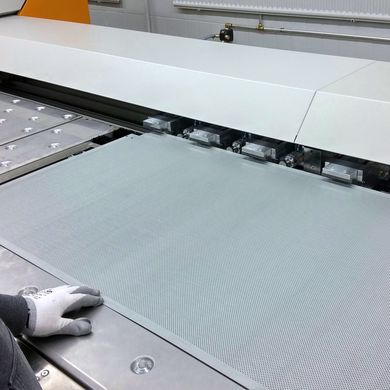

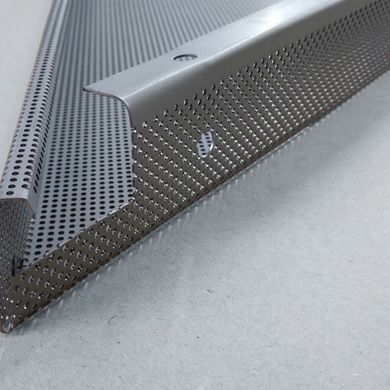

Perforated metal ceiling tiles

If you want to load perforated blanks from ceiling tiles automatically, the loading system needs to lift the blanks on the non-perforated frame and must deliver them to the Multibend Center panel bender. The automated RAS MiniFeeder loading system is in use at CBI Europe and is ideal for this job.

www.cbi-europe.it

Trapezoid metal ceiling panels

Hunter Douglas bends trapezoid ceiling panels with a Multibend Center panel bender. By repositioning the main manipulator during the bending sequence and the use of the automatic UpDownTools in the folding beam metal ceiling tiles can be bent with maximum precision and repeatability.

www.hunterdouglasgroup.com

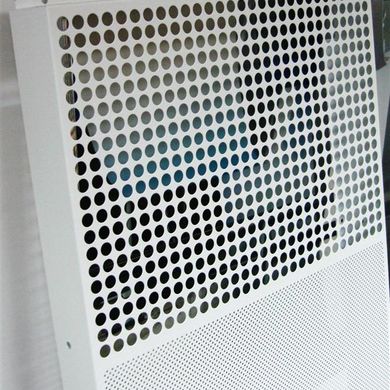

Perforated metal ceilings

SAS International is a world leader in the design and manufacture of precision engineered metal systems for suspended ceilings. The SAS UK manufacturing facilities rank amongst the most modern and fully equipped in the world. The Bridgend facility in South Wales manufactures ceiling tiles, and heating and cooling elements. Maybole in Scotland is responsible for special architectural metalwork. In 2007 SAS improved their production capabilities adding three automated folding systems RAS Multibend-Centers.

www.sasintgroup.com

- Multibend-Center 79.31-2: Metalldecken-Paneele

- Multibend-Center: Deckenkassetten manuell be-/entladen

- Multibend-Center: Schrägwinklige Metalldecken

- Multibend Center: Gelochte Rechteck-Decken

- Multibend-Center: Trapezförmige Deckenkassetten

- Multibend-Center: Dreieckige Metalldecken

- Multibend-Center: Gelochte Metalldecken

- 1

- 2