RAS machines for: Metal furniture and shop fittings

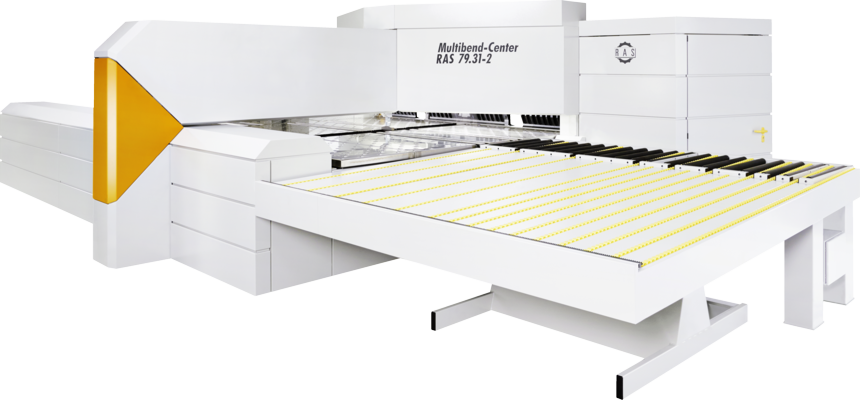

Freezers for blood reserves and vaccines

The Luxembourg company B Medical Systems is fully committed to automation. One component in this overall concept is the panel bender RAS Multibend-Center. It is connected to an automatic material storage system, which provides laser cut blanks to the automatic bending center. The finished parts are stacked by a robot for downstream assembly processes. The company specializes in refrigerators and freezers for the professional storage of blood reserves and blood plasma, human cells, tissues and other laboratory samples at extremely low temperatures. Freezers, which cool down to as low as minus 86 degrees Celsius, require a high level of manufacturing precision.

www.bmedicalsystems.com

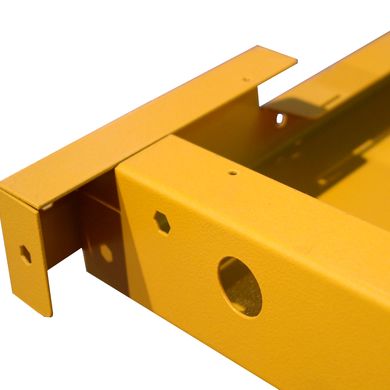

Components for shop floor cabinets

Döring GmbH & Co. KG comes from the field of contract manufacturing. However, today the metal specialist has their own product ideas that market themselves very well on the Internet. With the RAS Multibend Center, Döring pairs the manufacturing capabilities of the machine with their in-house design know-how, and develop creative solutions that do not yet exist in this form in the market. But they also bend panels for their own products such as cabinets for the equestrian sport, coffee pad holders and scrap containers.

www.doeringmarl.de

Futuristic office furniture and locker rooms

C + P Möbelsysteme is an innovative company in the metal furniture sector. On several Multibend-Center panel benders, complex parts are created for office and workshop furniture as well as locker cabinets. Starting with standard solutions, C + P also produces complete systems for high-level office and conference facilities and exclusive changing rooms for wellness oases.

www.cp.de

Workshop furniture: Three into one!

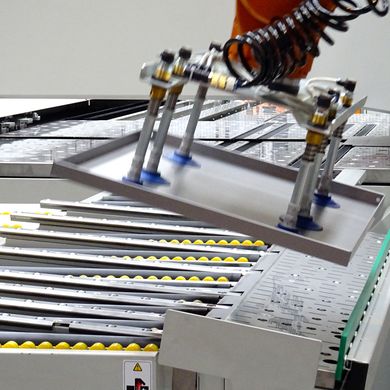

Bedrunka & Hirth produces shop floor furniture and uses the RAS Multibend Center mainly for metal furniture drawers. The intelligent loading robot places the blanks on the shuttle table, as they may not be flipped due to embosses having been formed into the blank before bending. The robot does not require any teaching or programming. This procedure eliminates welding and grinding of the drawer edges. The RAS Multibend-Center panel bender not only processes their parts faster, but also allows many product redesigns with fewer components.

www.bedrunka-hirth.de

Oblique laboratory furniture top panel

Henke GmbH has been a supplier of market-leading companies for many years. Nevertheless, the company was increasingly bothering foreign competitors. When a customer wanted to outsource an obliquely angled metal plate for a laboratory bench to a foreign competitor, the time had come for automatic bending. What used to take 45 minutes on two presses with two operators before, the Multibend Center now bends unmanned in 116 seconds plus 5 minutes of completion time.

www.henke-metall.de

Bending shop floor furniture

An intelligent loading robot feeds the RAS Multibend Center panel bender with punched blanks. There is no need to program or teach the robot. The blanks will be delivered to the bending center from an automatic storage system. After bending, an intelligent unloading robot grips and stacks the finished sheetmetal parts.

www.lista.com

Kit production of steel furniture components

The Multibend Center bending center is ideal for the flexible and needs-based production of small batches. The video shows the machine bending a tool cabinet in kit production. All parts belonging to a cabinet are manufactured one after the other. The tool changer automatically sets up the machine after each part change.

Bending refrigeration appliances

The video shows the UpDown acting folder RAS XLTbend bending metal components for refrigeration appliances. The complex parts were programmed with the unique Bendex software with just a single mouse click. Programming starts from a STEP file of the part. www.arneg.pt

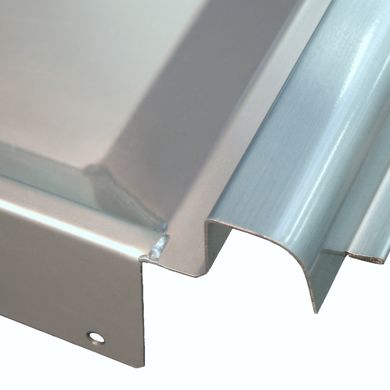

Bending refrigerated counters

Sheetmetal parts for refrigerated counters are usually very large and made of thin sheet metal. Especially when the parts in addition have positive and negative bends, handling becomes a big challenge. The RAS UpDownCenter panel bender offers an ideal solution. Thanks to the integrated tool changer and the automatic part programming software, even the smallest batches can be produced extremely profitable.

www.exkalsa.com

Medical panel

The video shows the RAS Multibend Center panel bender folding a panel for medical furniture. The blank is already pre-coated. The unique bending technology of the RAS Multibend Center does not damage the sensitive and visual metal surface during the forming process. Bending the complex drawer uses UpDownTools and Tab bending tools.

Bending store fittings with camera system

At the shop fitting specialist Wanzl the Multibend Center panel bender automatically loads the correct bending programs. A camera recognizes the blank geometry and the position of the blank. Based on this information the software loads the matching bending program and starts the loading robot. The robot loads the laser cut blank into the bending center, which bends shop fittings for supermarkets.

www.wanzl.com

Bending shelves

Bending of shelves requires bending flexibility features on a bending center. With its ability to form (linear) bending, the RAS Multibend Center panel bender provides ideal conditions for such complex forming operations.

- UpDownCenter: Medizintechnische Möbel biegen

- Multibend-Center: Blutkonserven

- XLTbend: Komponenten für Büromöbel

- Multibend-Center ECO: Biegeablauf Regalböden

- Multibend Center: Regalboden

- Multibend Center: Ladenbau – Kamerasystem

- Multibend-Center: Medizintechnisches Panel

- Multibend Center: Werkzeugschränke Kitfertigung

- Multibend-Center: Komplexe Büromöbelteile

- Multibend-Center: Werkstattschränke

- Multibend-Center: Werkstattschrank-Komponenten

- Multibend-Center: Klimaschränke für Labore

- Multibend-Center: Labormöbel aus Edelstahl

- Multibend-Center: Möbelsysteme aus Metall

- XLTbend: Kühlmöbel biegen

- Multibend-Center: Schubladenfertigung

- 1

- 2

- 3

- 4