RAS panel bending machines are fully automated systems that can be utilized in flexible or volume environments. The speed and throughput can match the same effort on up to six stand-alone machines.

The machines offer automatic tool changing and unmatched precision at high speeds for both small lot sizes as well as large volume production, maintaining the highest level of flexibility and repeatability.

Panel bending machines are ideal for medical, appliance, computer, elevator, and contract manufacturers of bent sheet metal products. The patented RAS swing-beam technique of bending does not mark cosmetic surfaces and ensures long tool life, equaling lower operating costs.

There are several advantages to owning a panel bending machine:

Easy to operate: Panel bending machines are easy to use and can be fed with different loading systems or by an operator with little or no training. Even the manually loaded machines only require the operator to place the panel in the machine and take out the finished product. Each model of RAS panel bender includes part verification to maintain precision, regardless of the loading operation. The bending quality remains totally independent of the operator.

No extra tools: With panel bending, virtually every bend angle and radius can be achieved with a single tool geometry.

Increased productivity: With the tool changer and fast changeover times, batch sizes can shrink. Production can be optimized based on real-time demand, while also reducing storage and handling.

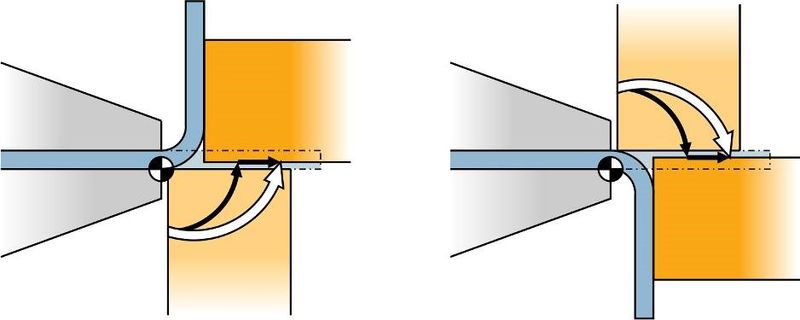

Precision bending: RAS manufactures the highest precision manipulator in the industry, with a positioning accuracy of +/- 0.0008” and rotation accuracy of +/- 0.001°. Our AC-servo motors are reliable, repeatable, and precise. The bending tools carry the flange up dynamically against our flat tool surface, remaining in contact with the outside edge throughout the bending movement. This eliminates flange twisting and guarantees straightness.

RAS MULTIbend Center

The RAS MULTIbend Center can be offered in 3 models: 85”, 100” and 120” bend lengths, with a flexible and modular design to integrate a large variety of loading and unloading solutions as needed. For added flexibility and economy, we offer each of the three lengths in an ECO variant to utilize manual load and unload at a lower cost while maintaining speeds.

Whether a small job shop or a high-volume OEM, the MULTIbend Center can be configured to meet the needs of any production environment. Look at the number of parts handled by multiple operators (put it on a RAS), the hours spent with setup for new parts (put it on a RAS), and the amount of rework from inconsistent parts (put it on a RAS).

RAS panel bending machines are designed to work in a variety of production environments. They offer the opportunity for growth into future automation up- and downstream, not to mention they safely remove the many hazards of manual bending from operators on the floor. You can expect cost savings through improved assembly, reduced scrap, and optimized part batching; all from adding a RAS panel bender to the line.

A variety of real-world applications with a multitude of integrations can be viewed here.

If you have any questions regarding panel bending machines please visit our website for more information or request a quote today!

Founded in 1939, RAS builds metal bending, cutting, and forming equipment, as well as fabrication software, and are known for high quality, reliability, and precision. Connect with the RAS team here!

Dynamic Edge Bending Process