Innovation at its best!

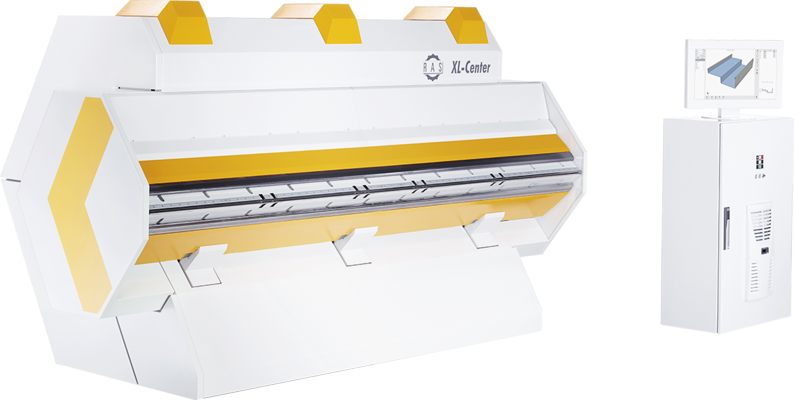

The XL-Center is an affordable machine for bending roof and wall profiles, designed for ease of use. Our innovative Bendex software and intuitive design allows you to complete operations with less staff, helping you save money.

XL-Center Highlights

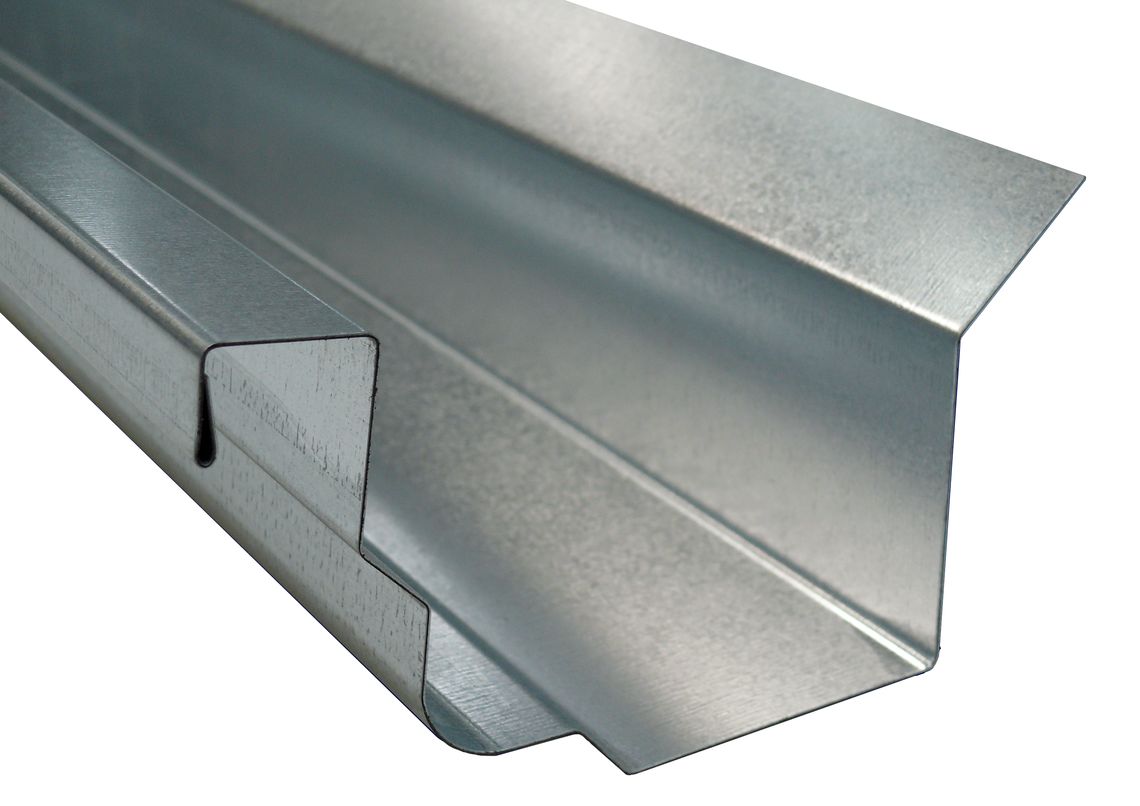

- Affordable machine for bending roof & wall profiles

- Bending up and down

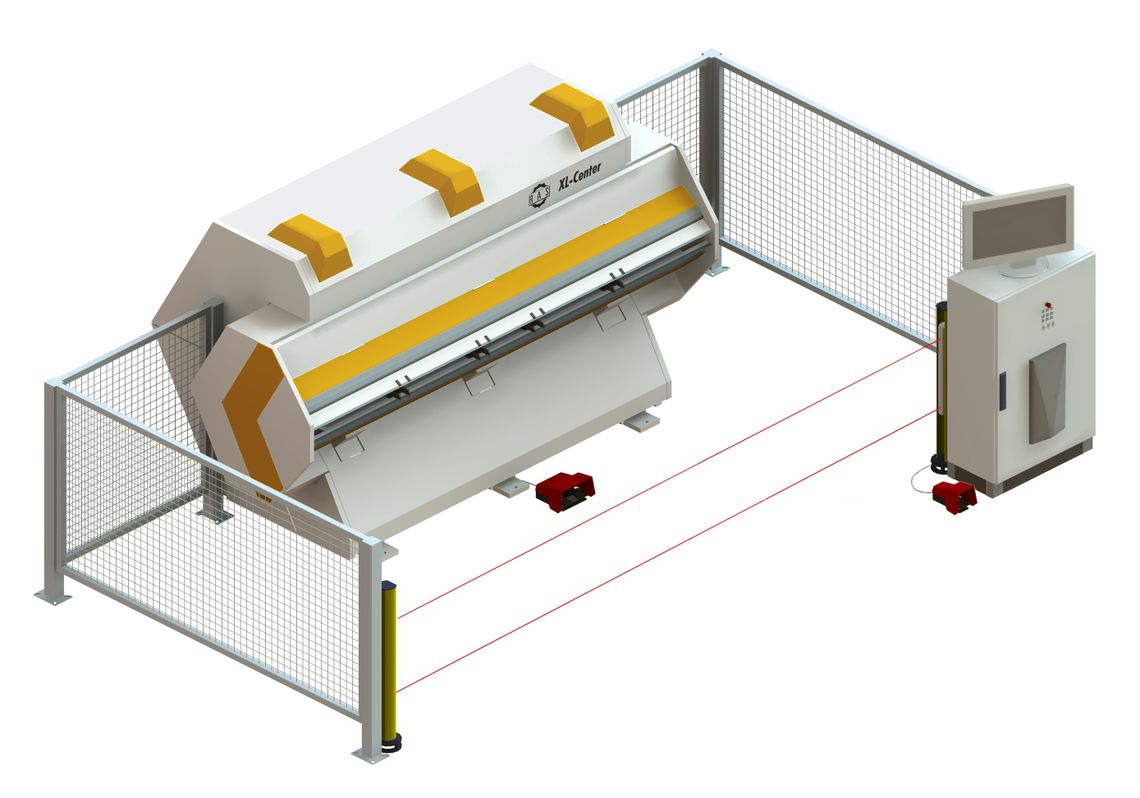

- Material handling reduced to a minimum

- Bending tapered profiles underline the extra class of the XL center

- 300 degrees free space allows for maximum part design flexibility.

- Unparalleled folding speed due to five servo-regulated motors

- Easy operation due to automatic 1-click part programming

- No bending expertise required

- Folding simulation in 2D or 3D

DOWNLOAD SPEC SHEET

Download our product brochure or production program to learn more about this machine, and all the other folding and bending tools RAS Systems has to offer.

Download

Download all information as PDF.

Download documents

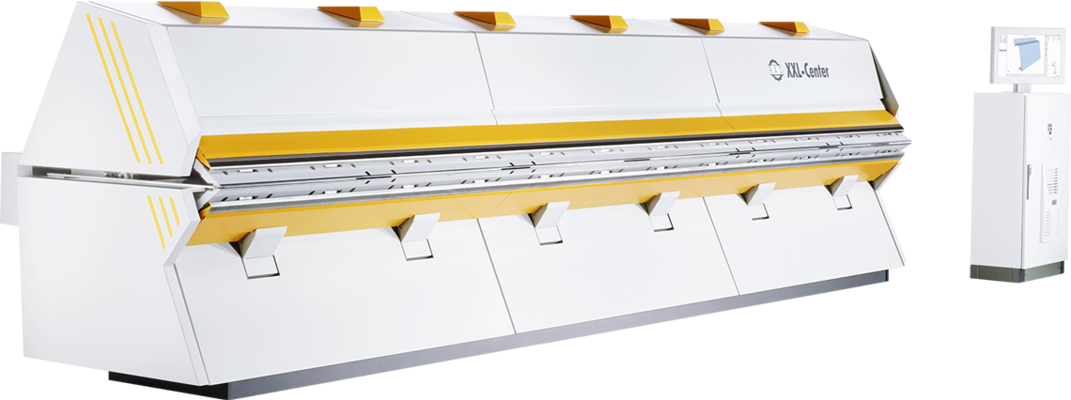

Similar products

Which products covers similar needs.

CompareSimilar Machines

Watch list

You can save as many products on your watch list as you like and inquiry them all together.