Is your metal fabrication business focused on efficiency and safety? If so, CNC folding machines may be right for you. CNC folding is a...

A Guide to CNC Folding: How it Could Benefit Your Metal Fabrication Business

read more

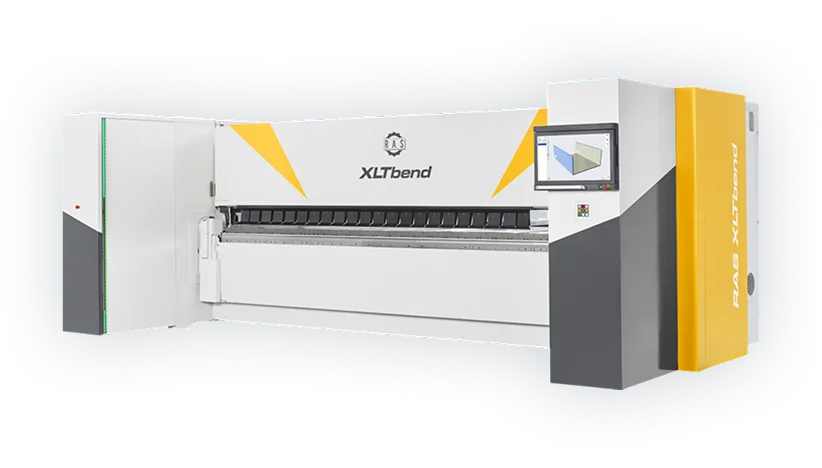

The XLTbend software has been created specifically for the XLTbend.

Import a part

Download all information as PDF.

Which products covers similar needs.

No comparable products available.

Is your metal fabrication business focused on efficiency and safety? If so, CNC folding machines may be right for you. CNC folding is a...

When it comes to metal fabrication, the equipment you choose for bending and folding your materials directly impacts your team’s workflow, product...

If your business is in a metal fabrication industry such as roofing, HVAC, automotive, etc, odds are you need to fold and bend metal parts...