Labor shortages are a real issue in the metal fabrication industry, with businesses looking towards software to overcome this challenge. In fact, automation and software were the two most important factors buyers sought to address when purchasing metal fabrication machines at FABTECH 2021.

Software helps metal fabrication businesses overcome some of the challenges associated with workforce shortages by making it easier for a new generation of employees to enter the industry. Additionally, software for metal bending machines can also lead to faster production times, greater efficiency, and increased profits.

RAS Software for Metal Bending Machines

RAS Systems has a long history of being at the cutting edge of software for metal fabrication machines. Our software allows visualization of the end product before the materials need to be taken off the shelf. Engineers use our software and Design for Manufacturing (DFM) while in the office. They can do this without interrupting production and continue to modify until they find a design that suits their requirements.

RAS software is designed and optimized for each machine and allows for 2D and 3D models and images for the parts operators are looking to create. This allows them to save money, time and valuable resources, all while improving accuracy.

Here are some of the features and benefits of the software used in RAS metal bending machines:

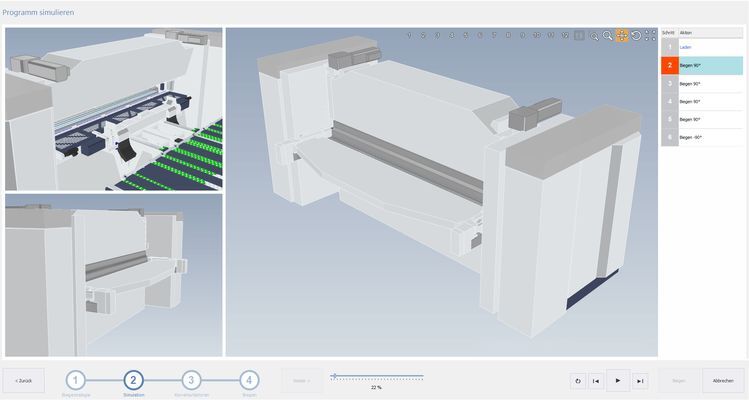

Multibend-Center & ProfileCenter: The software for the Multibend-Center and ProfileCenter allows for the import of a CAD file with the part model. The software analyzes the file and automatically generates a 3D model. For DXF files, the programmer has to add to the bend angle. Springback compensation angles are listed in the materials table. The software programs the parts automatically with a single click of the mouse.

The software can recommend the best alternative with a 5-star ranking if there are different folding sequences. The automatic programming in the software includes the loading and handling of the profiles.

XXL-Center & XL-Center: Created specifically for the XXL-Center and XL-Center, this software lets users draw a part on their office PC in 2D or 3D. The software can then provide a 2D or 3D detailed simulation of how the part will be created. The user can specify the color side and view the profile from any perspective. Alternatively, the user can enter flange dimensions and angles on the machine control and watch how the profile arises on the monitor. They also have the option of selecting a profile from the profile list and modifying flange dimensions and angles if needed, or they can import a profile that has been created on a tablet or PC on site. Similar to our other software, one-click programming is featured.

Turbo2plus & UpDownCenter-2: The software for Turbo2plus and UpDownCenter-2 lets users draw a profile on the monitor and add flanges to the 3D profile. CAD files with the part geometry can be imported with the software analyzing this file and automatically generating a 3D model. The one-click programming shows alternative folding sequences, and the automatically created program also includes the tool setup.

RAS also offers the Bendex Professional.shop and Bendex Professional.production software to optimize workflow and create clear production documents. With the JobControl Software, users can visualize the part on their smartphone, tablet, or PC. They can see the current status of the jobs, those that have been processed, and information about the machine status.

Contact us today to learn more about RAS software for metal bending machines.

Founded in 1939, RAS builds metal bending, cutting, and forming equipment, as well as fabrication software, and is known for its high quality, reliability, and accuracies.

Recent Comments