When it comes to metal fabrication, numbers are everything. From sheet metal sizes to sheet metal gauges and dimensions, every job requires ultimate precision. Whether you’re new to the industry or managing an established business, you’ll know that operating costs, product fit, and even the efficiency of your machines can all be directly impacted if your numbers are off.

So, how can your business ensure you’re following the right sheet metal sizes, gauges, and thicknesses? In this blog, we’ll break down the most common questions about how sheet metal is sized and labeled, helping you gain more clarity for your next project.

What Are Standard Sheet Metal Sizes?

When you’re looking for sheet metal, most will come in standard flat dimensions, commonly measured in inches or millimeters. For North American fabricators, the most typical sheet metal size is 4’ x 8’. However, this can vary depending on the type of material you use, as showcased by the chart below. Other common sizes are 4’ x 10’ and 5’ x 10’.

The actual sizing can vary based on the supplier or region. Some specialty or high-volume applications may also use custom cuts or coils. For larger OEMs or multi-part production runs, size is important because it affects how many parts can be nested per sheet. This has a direct impact on waste reduction and material efficiency, which can lower a project’s overall costs over time.

At RAS, our advanced metal cutting machines are designed for safer, more ergonomic part handling. Explore your options to see how you can unlock higher consistency when working with sheet metal of any size.

Sheet Metal Gauges, Decoded

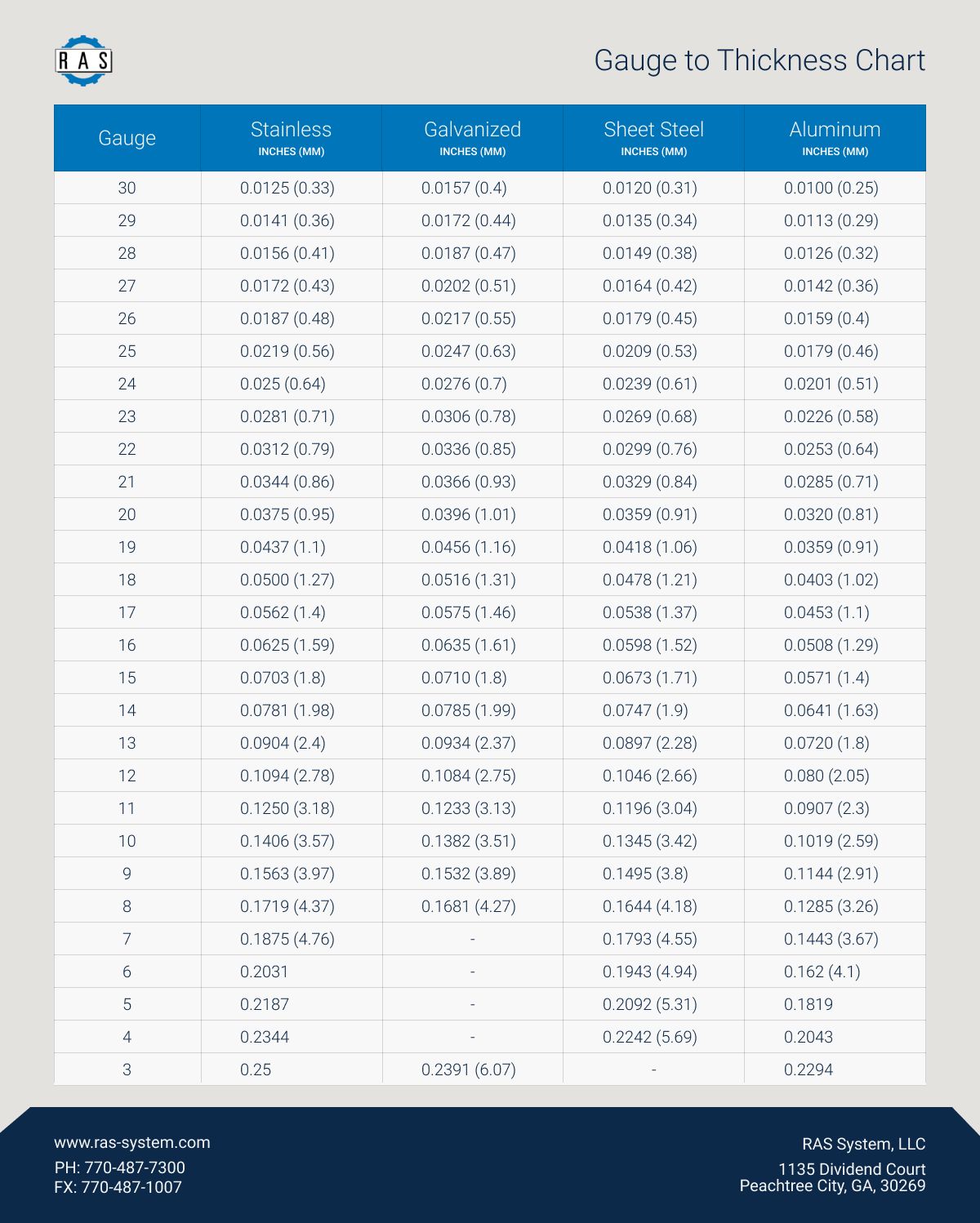

Sheet metal size tells you how big your material is. Sheet metal gauges tell you how thick it is. Here is the tricky part, though: gauge numbers don’t translate directly into a universal thickness. The same gauge can mean different thicknesses depending on the metal type your team is fabricating.

For example, if you’re using 16-gauge stainless steel, the sheet metal thickness will be around 0.0598 inches. If you’re using aluminum, however, it will be around 0.0508 inches thick.

The general rule of thumb when analyzing sheet metal gauges is that the lower the number, the thicker the metal. This relationship isn’t always perfect, though. When finding the right gauge for your project, it is crucial to do your due diligence when researching options.

Knowing the correct gauge helps ensure your chosen metal is compatible with your equipment, helping you avoid costly mistakes or project delays. If you’re unsure which gauge your machine can handle, RAS’s team of experts can help you match machine capability with your project demands. Be sure to get in touch with us or check out our tutorials page for other helpful tips.

Understanding Sheet Metal Thickness

While you’ll likely hear sheet metal gauge more frequently, actual thickness drives the performance of your fabrication process. That’s because the true thickness of a sheet, measured in inches or millimeters, plays a major role in everything from bending precision to structural strength of the completed product(s).

Here is why sheet metal thickness is important:

- Thicker metals require more force to bend or cut, often demanding more powerful machinery and specialized tooling.

- Thinner sheet metal sizes are easier to form but may warp or buckle under stress if not handled properly.

- Tolerances are tighter with high-precision jobs, especially in industries like data centers or electrical enclosures.

RAS folding machines, like the XLTbend or UpDownCenter-2, are engineered to account for these thickness variables. Combined with our innovative Bending 4.0 technology, operators can input material specs and let the machine do the math.

How RAS Machines Help You With Sheet Metal Size and Thickness

Finding the right sheet metal sizes is one thing. Having the right metal fabrication machine is another. Whether you’re working with thick gauge steel or delicate aluminum, RAS machines are engineered for precision, speed, and versatility across industries such as HVAC, data centers, and electrical.

Our fabrication machines offer:

- Wide Compatibility: From thin 26-gauge sheets to thick 3mm steel, RAS machines such as the Multibend-Center and MEGAbend offer industry-leading versatility.

- Material Intelligence: Features, including built-in sensors or adaptive programming, adjust bending dynamics automatically to match material thickness and properties.

- Expert Support: Our technicians work exclusively on RAS systems, so you get quick, specialized help to ensure your machine continues to operate efficiently.

To learn more about our fabrication solutions, contact us today. Our team offers consultations to help you find the right machine for your business’s unique fabrication needs and goals.

FAQs

What are the sizes of sheet metal?

Standard sheet metal sizes typically include 48″ x 96″, 48″ x 120″, and 60″ x 120″. Dimensions can vary based on material type and supplier, but these formats are common across most steel, aluminum, and stainless steel sheets.

What is the blank sheet metal size?

A blank sheet metal size refers to the raw, flat dimensions of a metal sheet before cutting or forming. It’s usually based on standard sizes like 4′ x 8′, but can also be custom-cut to fit specific fabrication needs.

Recent Comments