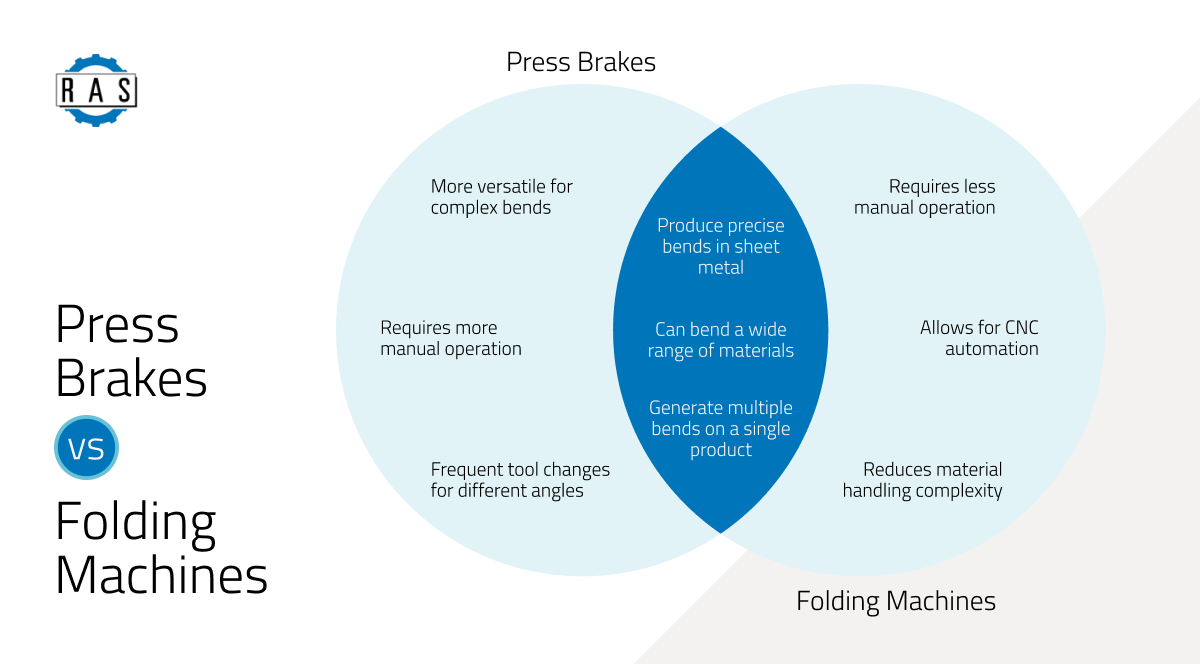

When it comes to metal fabrication, the equipment you choose for bending and folding your materials directly impacts your team’s workflow, product quality, and bottom line. One of the most common decisions business owners face today is whether to use a press brake vs. a folding machine for their operations. While both machines are designed to shape sheet metal, the way they do it—and the types of projects they’re best suited for—can be very different.

Understanding the advantages of metal folding machines and the capabilities of press brakes vs. folding machines is key to making the right investment for your business. No matter the type of metal sheets you’re working with, choosing the right bending solution is the most critical factor. The right machine can improve accuracy, reduce labor costs, and streamline your entire operation.

In this blog, we’ll break down the essential differences between press brakes vs. folding machines to help you decide which option aligns best with your business’s unique needs.

Understanding Folding Machines vs. Press Brakes

Although press brakes have been the traditional choice across many metal fabrication industries, metal folding machines are worth considering. Folding machines are designed for high precision and efficient sheet metal processing. Companies often associate the term “panel bender” with folding machines, however, panels are just one of the products that folders can form. These machines are ideal for projects that require complex bends with high accuracy and minimal handling. A folding machine uses a motion that minimizes stress on materials, making it an excellent choice for delicate or pre-finished materials.

Folding machines have their own unique bending process vs. press brakes. One of the biggest advantages of metal folding machines is that the parts rest on the support table and do not require operators to lift, support, or hold them. This can help your business complete jobs up to 3X faster than press brakes. To learn more about the differences in setup, bending, and more, check out our metal folding vs. press brake guide.

When handling metal sheets that are 5 feet in width or over, folding machines are a better option due to their safer, more manageable operational dynamics. Folding machines, vs. press brakes, keep the material flat on the back gauge table and avoid directing metal sheets toward the operator, which enhances safety and handling ease.

Folding machines also offer pre-aligned upper beam and lower beam tools, which significantly minimize tool set-up time. This allows fabricators to switch from one part to another quickly, which is crucial under today’s pressures of small lot sizes and large volume requirements.

When are Press Brakes a Better Choice vs. Folding Machines?

Press brakes have been a cornerstone of metal fabrication for nearly a century, featuring a punch-and-die mechanism that excels in handling large production runs and thicker materials.

The biggest disadvantage of press brakes may be their considerable setup time—a factor that business owners who need quicker turnarounds should consider. With this said, however, their versatility and capacity to bend thick sheets of metal make them a good option for heavy-duty applications. Press brakes may also be better suited for tight, complex bends vs. metal folding machines.

Press Brakes vs. Folding Machines: Making the Right Choice

When the time comes to decide between press brakes vs. metal folding machines, here are some additional factors to keep in mind:

Material Handling: If you are working with heavy or large panels that require two operators to handle, folding machines are a more suitable option vs. press brakes.

Material Variety: Press brakes offer versatility and can bend heavier materials. However, folding machines like the RAS MEGAbend and RAS GIGAbend are capable of bending .25” mild steel.

Complexity of Bends: Versus press brakes, an advantage of folding machines is that they excel in precise, complex bends with fewer setups and tooling changes.

Space and Energy Efficiency: Folding machines generally occupy less space and are more energy-efficient, making them ideal for workshops with limited space or those looking to reduce operational costs.

Both folding machines and press brakes offer significant benefits, but the choice depends largely on the specific requirements of your projects.

At RAS Systems, we offer the finest metal fabrication machines for modernizing your business. Whether you’re bending, cutting, or forming, our game-changing machines will help you deliver the best results on every job. Interested in learning more about our equipment? Check out our selection of folding machines to see our capabilities, or book a consultation. Our expert sales team will reach out to learn what you’re creating and recommend the best machine for your business goals.

FAQs

What is a press brake machine?

Press brakes are one of the most popular metalworking machines. They typically operate by clamping a piece of metal between a movable punch and a stationary die to create predetermined shapes and angles. Press brakes have some disadvantages, including slower speeds than metal folders.

What is a metal folding machine?

Metal folding machines use specialized folding beams to bend workpieces, which remain flat on a support table. The method helps reduce material stress and part handling, which is especially beneficial for teams working with larger or thinner metal materials. Folding machines come with several benefits vs. press brakes, including fast and efficient results.

Should I choose a press brake or a metal folding machine?

When deciding between folding machines vs. traditional press brakes, you may want to consider your business’s production needs. For example, if your business is working with more sensitive materials, a metal folding machine comes with several benefits. However, if you’re looking for versatility in bending heavier materials, press brakes may be the right choice. At RAS Systems, our folding machines are designed to save your team time and money. Be sure to explore our options today!

Recent Comments