Want to know how you can stand out in today’s saturated fabrication market? Prioritize speed, precision, and efficiency. Whether you’re a small job shop or an enterprise-level fabricator, the ability to efficiently complete jobs can set you apart from your competitors, earning you more high-margin work in the process.

So, how can you achieve this? It starts with understanding the top sheet metal fabrication techniques and how they play into specific projects. By rethinking your sheet metal production process, you can stay competitive, reduce labor dependency, and deliver higher-quality results faster.

In this guide, we’ll explore four of the foundational sheet metal manufacturing methods, highlighting how innovations such as RAS folding machines and automation software give fabricators a considerable edge where it counts most: on the floor, in the field, and in your bottom line.

Sheet Metal Fabrication Techniques at a Glance

Before we dive into the specifics of each technique, let’s quickly establish the broader sheet metal production process. From initial ideation and design to final assembly, each stage contributes to the overall quality and scalability of your end product.

Here is a high-level overview of what a typical workflow could look like:

- Design & Engineering: Before you cut, fold, or form your parts, you first need to develop precise blueprints. CAD modeling is a common technique to achieve this, helping you set the foundation for accuracy and repeatability in downstream processes.

- Material Selection: The type of sheet metal you use, such as aluminum, stainless steel, or copper, directly impacts the fabrication technique. Depending on which material you decide to fabricate, you may need to adjust for cutting speeds, bending tolerances, and more.

- Cutting: In this stage of the sheet metal production process, raw materials are sized and shaped using techniques that include laser cutting. This is the first physical transformation from stock material into a usable part.

- Forming & Bending: Next, it’s time to define the part’s shape. This is arguably the most important sheet metal fabrication technique. While traditional, older machines offer familiarity, modern folding machines, including the RAS Multibend-Center, offer superior ergonomics, safety, and speed for every project.

- Joining: After parts are shaped, this stage of the sheet metal production process joins parts using welding, adhesives, bolts, or rivets, depending on application requirements.

- Finishing: Finally, you may choose to use powder coating, painting, or deburring to bolster the appearance and durability of your finished product(s).

How Today’s Top Fabricators Can Optimize Cutting

The cutting stage of the sheet metal production process is critical for laying the foundation for what comes next. If you’re in HVAC, server racks, or roofing, you know that clean, efficient sheet metal cuts can make or break the finished part quality.

So, what are some of today’s most popular methods for this sheet metal fabrication technique?

Laser Cutting

- For projects that require extreme precision

- Ideal for complex geometries and tighter tolerances

- Best for thin to medium-gauge materials

- May require higher up-front costs

Plasma Cutting

- Fast and cost-effective for thicker materials

- Slightly less precise than laser cutting

- Used frequently in industrial and structural fabrication

Waterjet Cutting

- A cold-cutting process with no heat-affected zones

- Used for metals, composites, or stones

- Slower than laser or plasma cutting

Shearing

- Mechanical cutting with straight-line cuts

- Ideal for quick sizing and trimming

- Common in high-volume operations

Bending & Folding: The Precision Sheet Metal Fabrication Technique

Bending is where the great fabricators truly make their mark. This stage of the sheet metal production process is where flat parts gain structure, rigidity, and function. It’s important to keep in mind, however, that speed matters. That’s why more leading businesses are switching to our high-tech forming machines.

Press Brakes vs. Folding Machines

Although traditional press brakes still hold power in today’s industries, they do have limitations. Press brakes:

- Are more common in job shops

- Require skilled operators to carefully set up

- Are limited during more complex bends

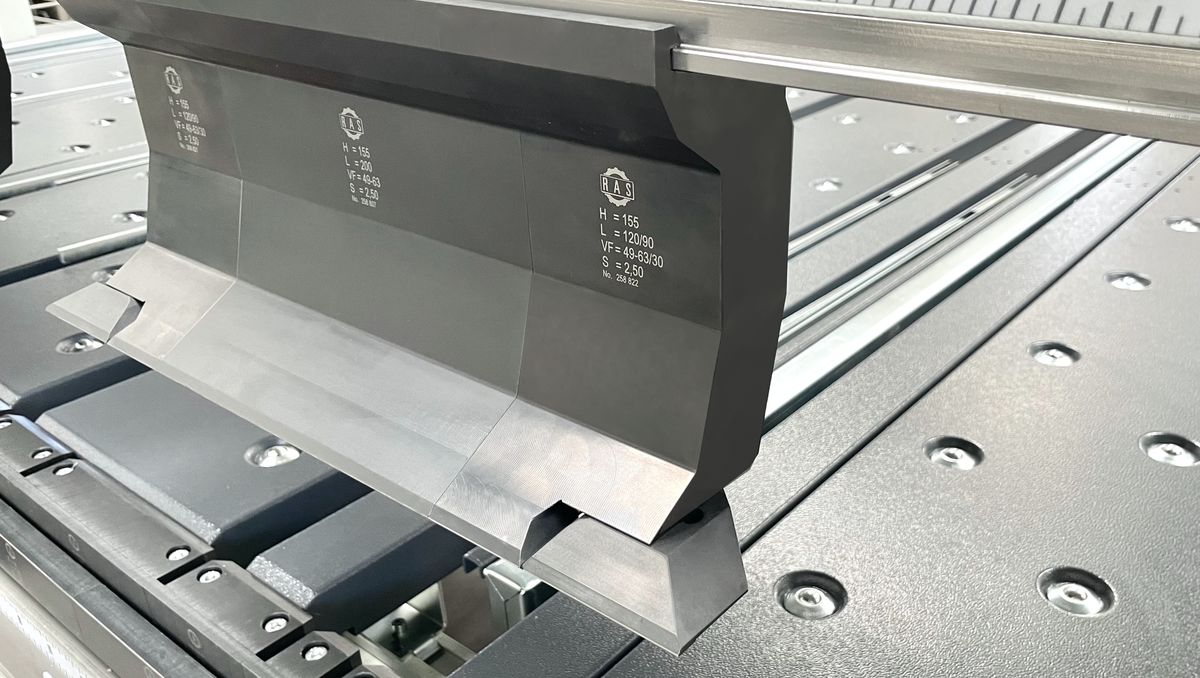

Folding machines from RAS, however, come with plenty of benefits. On top of minimizing the strain of physical labor, folding machines:

- Are safer and more ergonomic to operate

- Require less skill and training to operate

- Produce more accurate bends faster

- Reduce cycle time and can complete jobs 3x faster than press brakes

How Automation’s Role in Sheet Metal Fabrication Techniques is Growing

No matter which sheet metal manufacturing method you use, the ability to seamlessly link design and production is a game-changer. Through CAD/CAM integrations, operators can transition from digital files to finished bends without any guesswork or manual programming tweaks on the fly. This can help your business reduce human error and boost productivity over time.

RAS Bendex Software is at the heart of this transformation. Built to simplify the most complex folding jobs, Bendex allows operators to:

- Run automatic bending sequences from 3D part files

- Visualize every bend before production

- Adjust parameters for material type, thickness, and tolerance

- Store and recall jobs for faster repeat runs

If your sheet metal fabrication technique is ready to be optimized, RAS Systems has the solution for you. Request a quote today to speak with our team of experts. We’ll help you find the right folding machine and software products to fit your unique needs and production goals.

FAQs

What is a sheet metal fabricator?

A sheet metal fabricator cuts, bends, and forms metal into functional parts or products using precision tools and fabrication techniques.

What is precision sheet metal fabrication?

Precision sheet metal fabrication involves advanced equipment and software to produce highly accurate components with tight tolerances. Think industries such as aerospace, data centers, and electronics.

What is sheet metal fabrication software?

Fabrication software allows your team to automate bending sequences. This helps you achieve better accuracy and simplify your project programming.

How is sheet metal manufactured?

Sheet metal is manufactured by rolling metal slabs into thin, flat sheets, then cutting, forming, joining, and finishing them into parts for industrial and commercial applications.

What is sheet metal fabrication?

Sheet metal fabrication is the process of cutting, bending, forming, and assembling metal sheets into finished parts or structures. It is common in industries such as HVAC, roofing, and data centers.

Recent Comments