Innovation at its best!

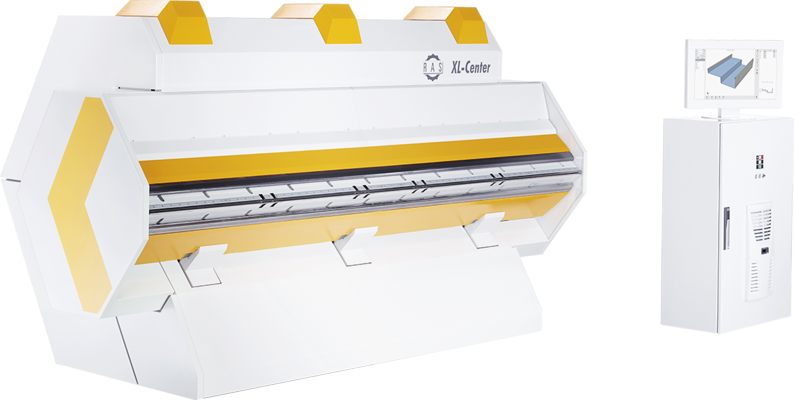

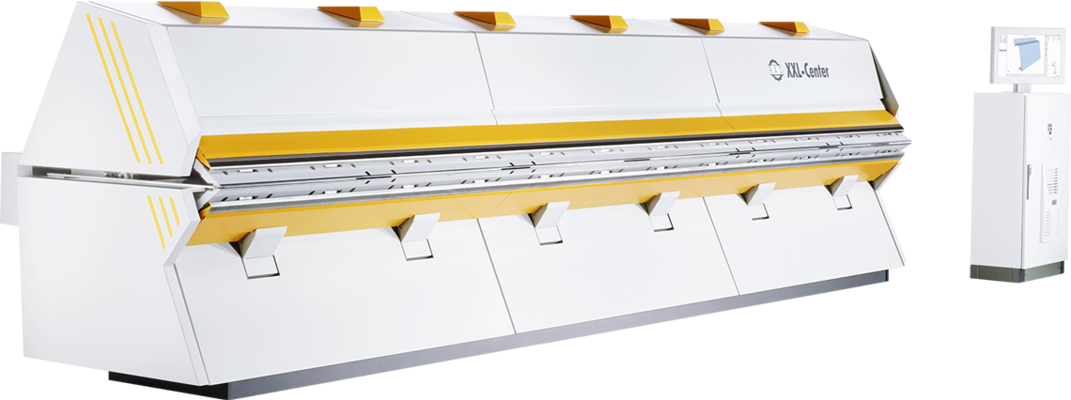

The XL-Center is an affordable machine for bending roof and wall profiles, designed for ease of use. Our innovative Bendex software and intuitive design allows you to complete operations with less staff, helping you save money.

XL-Center Highlights

- Affordable machine for bending roof & wall profiles

- Bending up and down

- Material handling reduced to a minimum

- Bending tapered profiles underline the extra class of the XL center

- 300 degrees free space allows for maximum part design flexibility.

- Unparalleled folding speed due to five servo-regulated motors

- Easy operation due to automatic 1-click part programming

- No bending expertise required

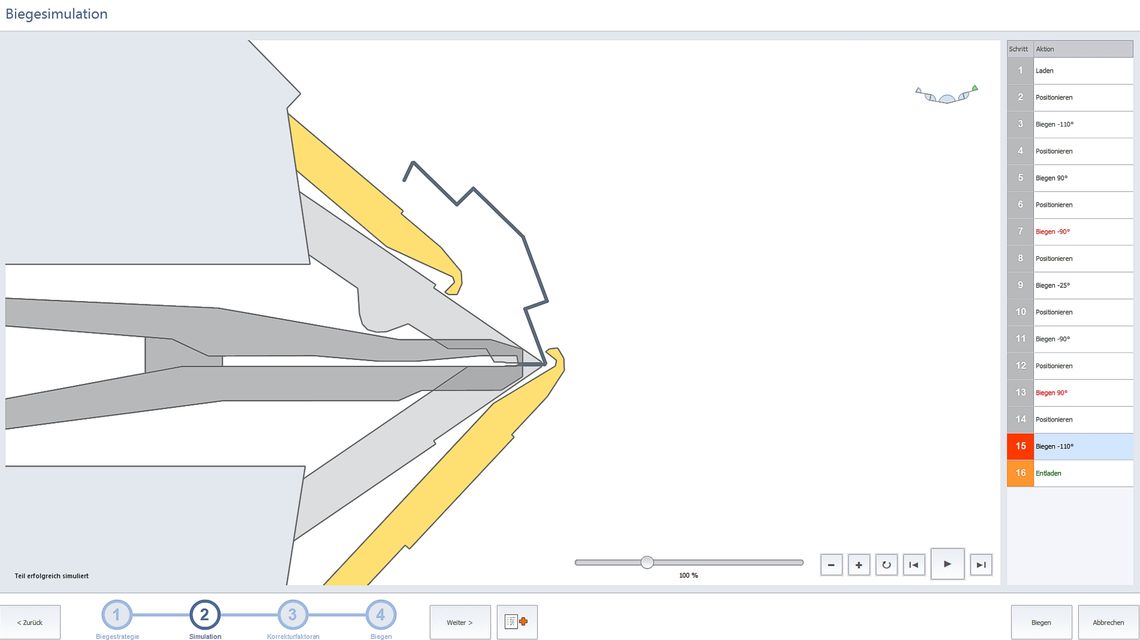

- Folding simulation in 2D or 3D

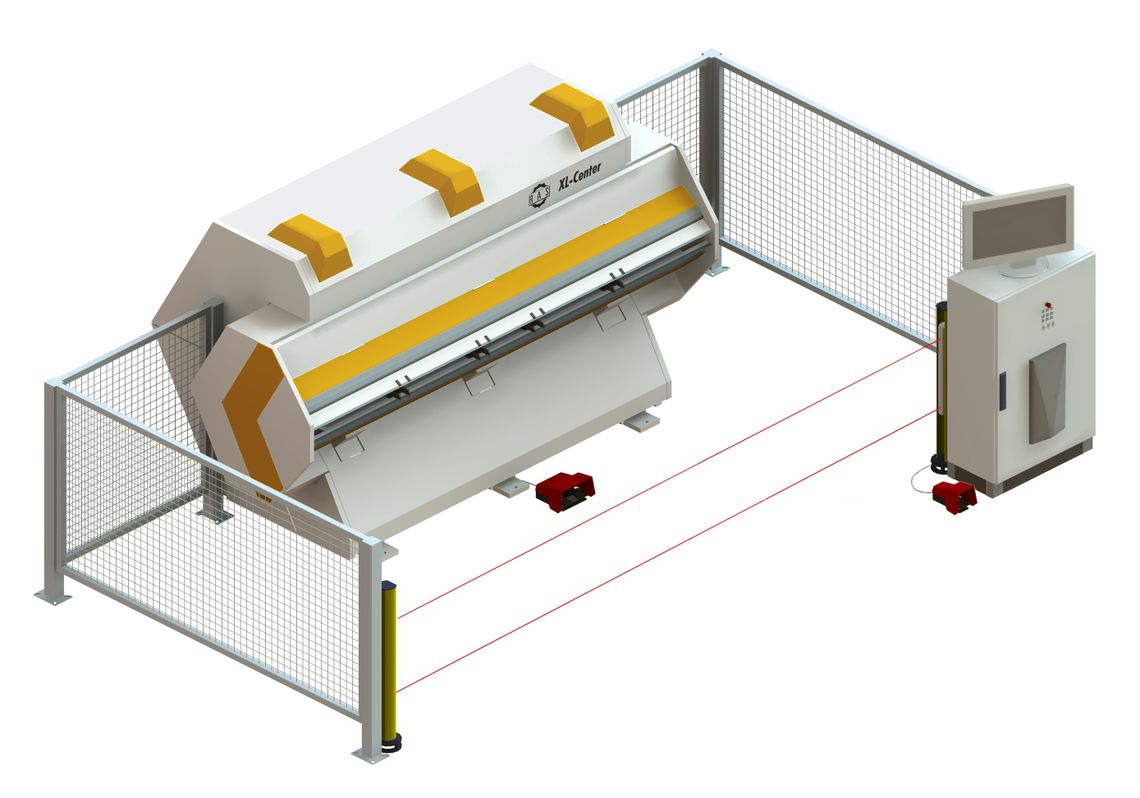

Automated bending

Grip, hold, position

After the blank is loaded the grippers of the XL-Center take over the workpiece and automatically position the part for each bend. The grippers can clamp on straight material, but can also clamp on a closed hem.

- Gripper position the part automatically for each bend

- Accurate and repeatable flange dimensions

- Fast bending sequences, high productivity, low costs per part

- Automatic re-grip sequence

Bending up and down

Up and down folding eliminates a need to rotate the parts. Short cycle times, precision flange dimensions and angles, high levels of productivity and low costs per part guarantee a quick payback of the investment.

- No part flipping required

- Little swivel movement of folding beams

- Fast bending sequences

- High productivity, short payback period

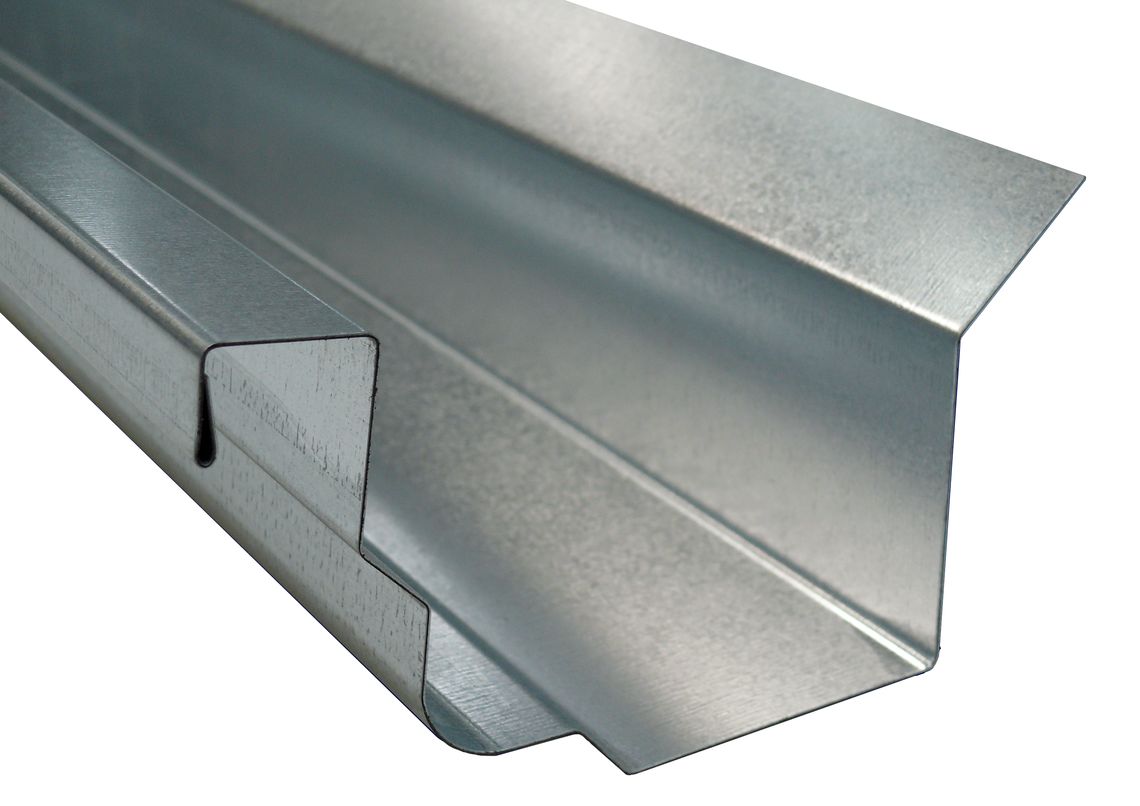

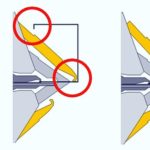

Tapered parts

If the working length of the XL-Center is not long enough, tapered bent profiles can be connected to each other.

- Perfectly matching tapered profiles

- Tapered side selectable with one mouse-click

- No programming effort

- Software calculates blank loading position

- No material bracing. Entire backgauge moves to a tapered position

Bending complex parts

RAS has designed XL-Center with maximum free space in front of the folding beams and has also patented this aspect. The extremely large free area of 300 degrees creates room for the most complex part geometries.

- Umlimited part design flexibility

- Folding beam already inside the part for the next bend

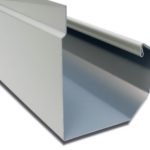

Perfect material surfaces

The tools roll away with the blank and fold them without scratching pre-painted materials.

- Scratch-free bending of sensitive materials

- No build-up of zinc abrasion

- No tool wear

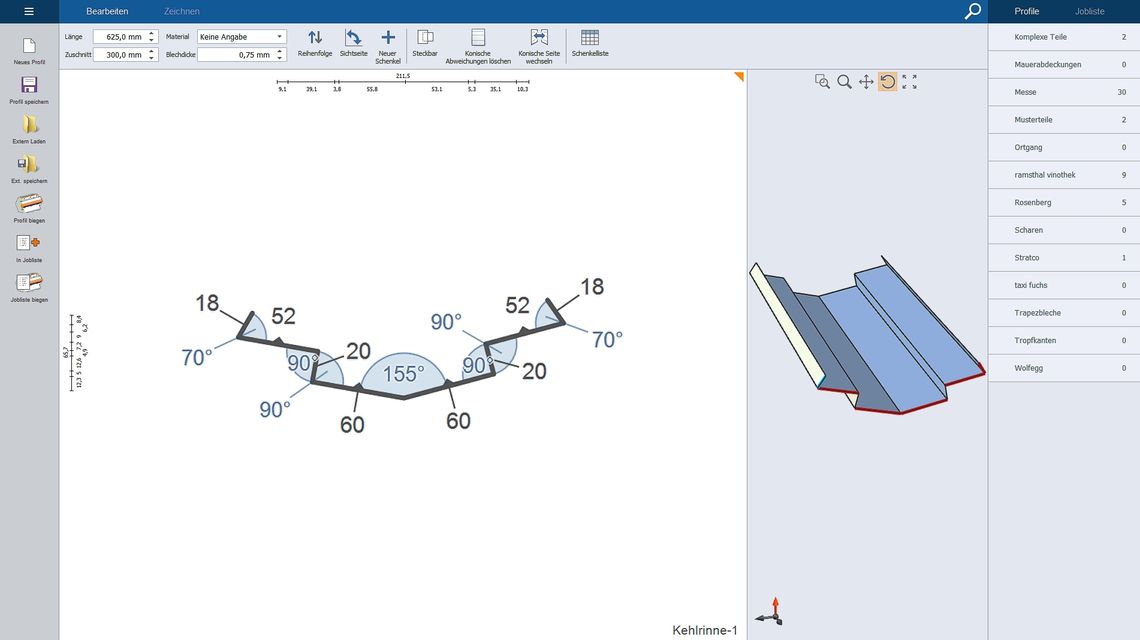

Automatic part programming

The operator draws the profile of the touch monitor or in the office using the Office software. The Bendex software automatically programs the part and suggests the optimum bending strategy. The software simulates the entire program cycle in either a 2D or 3D view.

- Dimensions and angles clearly visible even on complex profiles

- Automatic programming of the bending sequence with a single mouse-click

- Including tapered part calculation

- No bending expertise required

- Software suggests the best bending strategy with a 5-star ranking

- 2D or 3D bending sequence simulation

- Visualizing possible collisions

- With Office-Software: Programming and feasibility study in the office

Program features

The unique and powerful Bendex software automatically programs the parts. Its enormous fetaure list increases the throughput and productivity of the machine many times over.

- Material and thickness selection (Auto angle correction)

- Hems: close, open, drop-shape

- Radius bending

- Calculation of tapered parts

- Unfolded blank calculation (inside dimensions)

- Profile archieve, Joblists, Similar part search feature

- Order processing with Bendex software (Professional / Ultimate)

- Online-Support via TeamViewer

- Online Software Updates

Loading programs with a Matrix Code

Process optimization is so easy! While cutting just stick a QR code on the blank. At the XL-Center you only have to scan the code and the machine automatically loads the part.

- No input errors

- Fast and flexible program change

- Do n ot loose track at any time

- Blanks do not need to be processed immediately

Technical data

| Technical Data (mm) | XL-Center |

|---|---|

| Folding length | 3200 mm |

| Bend angles up to 90 degrees | |

| Material thickness max (400 N/mm²) | 1.5 mm |

| Material thickness max (700 N/mm²) | 1.0 mm |

| Material thickness max (200 N/mm²) | 2.0 mm |

| Bend angles more than 90 degrees | |

| Material thickness max (400 N/mm²) | 1.25 mm |

| Material thickness max (700 N/mm²) | 0.75 mm |

| Material thickness max (200 N/mm²) | 1.5 mm |

| Free space in front of the beams | 300° |

| Grippers | yes |

| Bending tapered parts | yes |

| Programming | automatic |

| Machine dimensions (normal setup) | 5400 x 3700 mm |

| Machine dimensions (compact setup, higher fences) | 3850 x 3700 mm |

| Technical Data (inch) | XL-Center |

|---|---|

| Folding length | 3200 mm |

| Bend angles up to 90 degrees | |

| Material thickness max (58,000 PSI) | 16 ga mild steel |

| Material thickness max (101,500 PSI) | 20 ga stainless steel |

| Material thickness max (29,000 PSI) | 14 ga aluminum |

| Bend angles more than 90 degrees | |

| Free space in front of the beams | 300° |

| Grippers | yes |

| Bending tapered parts | yes |

| Programming | automatic |

| Machine dimensions (normal setup) | 213″ x 145″ |

| Machine dimensions (compact setup, higher fences) | 152″ x 145″ |

Success Stories

Digitizing the Construction Site!

Stefan Bern is a roofing and façade specialist for demanding residential buildings. With a team of 30 employees, the company produces all metal parts in their workshop. Their own skilled workers assemble the profiles on large private properties in the area. With the RAS XL-Center, the company has significantly increased its efficiency and bending speed.

Applications

Bending double material

By adding manual bending sequences, the variety of possible profiles can be significantly increased. The software also calculates like the right upper beam clamping dimension when clamping on and bending of double material.

Bending materials with holes

Bending of stretched or perforated materials results in exact flange dimensions, as the blanks are clamped between the upper and the lower beam.

Download

Download all information as PDF.

Similar products

Which products covers similar needs.

Compare