Fully Automatic Part Bender

The future of panel bending is here.

What if you could bend precision parts fully automatically, at high speeds, in high quantity, regardless of batch size, with the highest levels of flexibility and total repeatability?

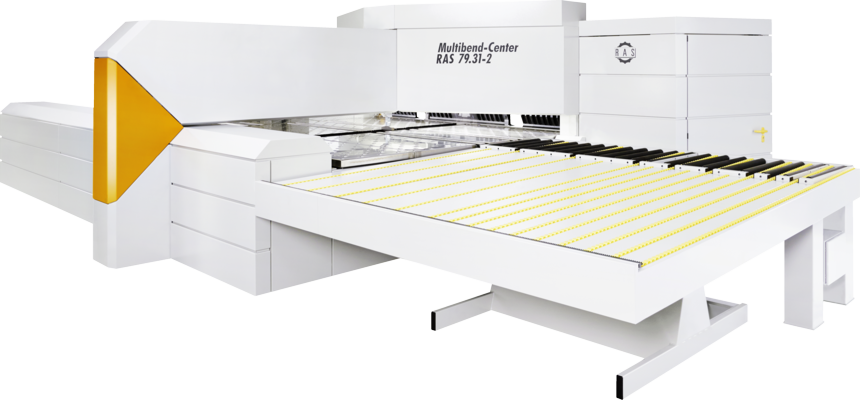

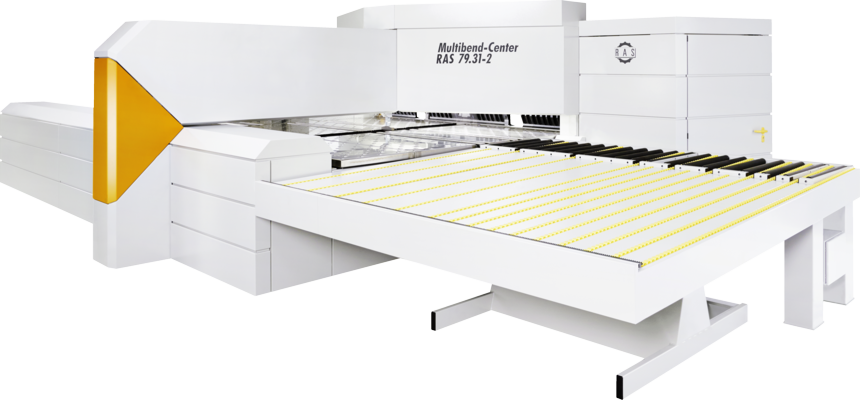

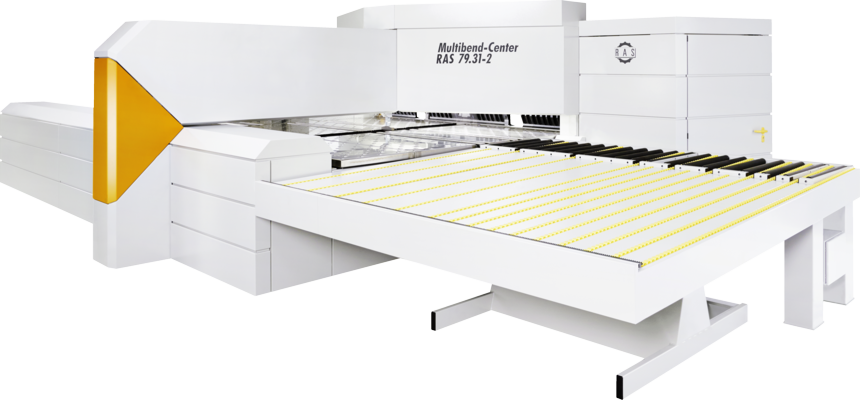

Meet the Multibend-Center: a fully automated bending and folding machine with the capabilities to become the foundation for your company’s success. With attachments available for optimized loading and unloading and tools for small and narrow parts, it’s easy to customize this machine to fit exactly what your business needs. Image

Multibend-Center Highlights

- Automatic loading, squaring, bending, and unloading

- Automatic folding sequences to create the highest level of productivity

- Automatic tool setup

- Highest level of precision and repeatability

- Scratch-free bending with no tool wear

- One-click part programming

- Numerous options for blank loading and part unloading

- Versatile modular layout design with options for upgrades and connection to other handling systems

Request a Quote

Contact us to get started on purchasing a folding machine for your facility.

Details & Options

Versatile Blank Loading Options

The Multibend-Center provides several blank loading options. Gantry loaders can include suction cup frames that can be installed with or without a QR code scanner, gantry loaders with our SheetFlipper, and robotic blank loading with suction cups and magnets. We also offer MiniFeeder options that can load different types of blanks without being programmed or taught. Each of these options allows for different benefits, so you can find the best method for your business needs.

Brush Tables and Small Part Feet

The Multibend-Center can be configured with optional brush tables, and small or narrow manipulator feet to allow for applications with small or narrow parts. These tools are ideal for industries that work with folds and bends on small and detailed profiles.

Unloading Parts

The Multibend-Center offers several different tools for the automatic unloading of parts. We offer tools including a runout with pusher belt that can direct parts to different downstream operations or assembly lines or belt conveyors for smooth and gentle transport of bent parts that can be connected to an unloading robot or Palletizer.

Palletizer Unloading System

Connecting to the end of the Multibend-Center, the Palletizer automizes the unloading and stacking of bent parts. Available with different options, the Palletizer can stack parts on a single pallet or serve multiple stacking positions safely. The intelligent robot unloading of the Palletizer allows for parts to be run on an unmanned shift. Our robotics system doesn’t require programming or to be taught; just select a stacking strategy and let the robot do the rest!

Technical Data

| Technical Data Multibend-Center (mm) | RAS 79.31-2 | RAS 79.26-2 | RAS 79.22-2 |

|---|---|---|---|

| Working length | 3060 mm | 2560 mm | 2160 mm |

| Material thickness max (400 N/mm²) | 2.0 mm | 2.0 (2.5) mm | 2.0 (2.5) mm |

| Box height max (four sides) | 203 mm | 203 mm | 203 mm |

| Blank length max | 3160 mm | 2660 mm | 2260 mm |

| Blank width max | 1500 mm | 1500 mm | 1500 mm |

| Dimensions (Basic machine) | 8650 x 6100 mm | 5900 x 5800 mm | 5100 x 5400 mm |

| Technical Data Multibend-Center (inch) | RAS 79.31-2 | RAS 79.26-2 | RAS 79.22-2 |

|---|---|---|---|

| Working length | 120.4″ | 100.8″ | 85″ |

| Material thickness max (58,000 PSI) | 14 ga | 14 (13) ga | 14 (13) ga |

| Box height max (four sides) | 8″ | 8″ | 8″ |

| Blank length max | 124.4″ | 104.7″ | 88.9″ |

| Blank width max | 59″ | 59″ | 59″ |

| Dimensions (Basic machine) | 340″ x 240″ | 232″ x 229″ | 201″ x 213″ |

Success Stories

Strengthening Internal Products

Döring GmbH & Co. KG comes from the field of contract manufacturing. However, today the metal specialist designs its own product ideas. Döring sells these products mainly on the internet. With the RAS Multibend-Center, Döring pairs the manufacturing capabilities of the machine with their in-house design know-how and develops creative solutions that do not yet exist like this on the market.

Download

Download all information as PDF.

Similar products

Which products covers similar needs.

CompareRequest a Quote

Add this product to your watchlist.

Add to watchlist or Request directly

Similar Machines

Multibend-Center 79.31-2 |

Multibend-Center 79.26-2 |

Multibend-Center 79.22-2 |

Multibend-Center 79.26-2 ECO |

Multibend-Center 79.22-2 ECO |

UpDownCenter 78.33-2 |

UpDownCenter 78.43-2 |

UpDownCenter 78.30-2 |

UpDownCenter 78.40-2 |

XLTbend 71.30 |

XLTbend 71.40 |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | Add to watchlist | |

| Bending length max | 3060 mm | 2560 mm | 2160 mm | 2560 mm | 2160 mm | 3200 mm | 4060 mm | 3200 mm | 4060 mm | 3200 mm | 4060 mm |

| Thickness max | 2.00mm/14 ga | 2.0 mm (2.5 mm) / 14 ga (13 ga) | 2.0 mm (2.5 mm)/14 ga (13 ga) | 2.0 mm / 14 ga | 2.0 mm / 14 ga | 4.0 mm / 9 ga | 3.0 mm / 11 ga | 4.0 mm / 9 ga | 3.0 mm / 11 ga | 3.0 mm / 11 ga | 2.5 mm / 13 ga |

| Programming | automatic | automatic | automatic | automatic | automatic | automatic | automatic | automatic | automatic | automatic | automatic |

| Automation | high | high | high | high | high | high | high | high | high | high | high |

| Bending direction | up and down | up and down | up and down | up and down | up and down | up and down | up and down | up and down | up and down | up and down | up and down |

| Parts | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes | Profiles and boxes |